Recentemente, o conceituado YouTuber americano rctestflight (Daniel) concluiu com sucesso um projeto entusiasmante utilizando o Flashforge Guider 3 Ultra – construindo o moto de neve R/C mais rápido do mundo! O vídeo deste projeto recebeu milhões de visualizações e milhares de gostos no YouTube, demonstrando as incríveis vantagens da impressão 3D no fabrico personalizado. As capacidades de impressão de alta precisão do Guider 3 Ultra ajudaram a satisfazer os requisitos de desempenho mecânico e precisão de montagem do snowmobile, fornecendo um sólido apoio técnico para o sucesso do projeto.

Desafios e Inovação

Estou a começar do zero e a abandonar completamente o sistema de energia acionado por engrenagens, utilizando motores elétricos de skate. Têm um binário significativo, o que significa que normalmente podem ser utilizados com redutores de engrenagens muito pequenos, ou mesmo acionados diretamente, no caso dos motores de cubo.

– Daniel, rctestflight

"Personalização criativa para velocidade máxima" foi o conceito central deste projeto de motas de neve, o que significava que cada peça tinha de ser altamente personalizada. Isto representou enormes desafios para a resistência, estabilidade e precisão do encaixe da estrutura da carroçaria do moto de neve. O Guider 3 Ultra superou as expectativas, imprimindo uma vasta gama de peças complexas e críticas, incluindo a carcaça de proteção do motor, as laterais da carroçaria, os apoios do eixo e as rodas.

Design inovador, produção rápida

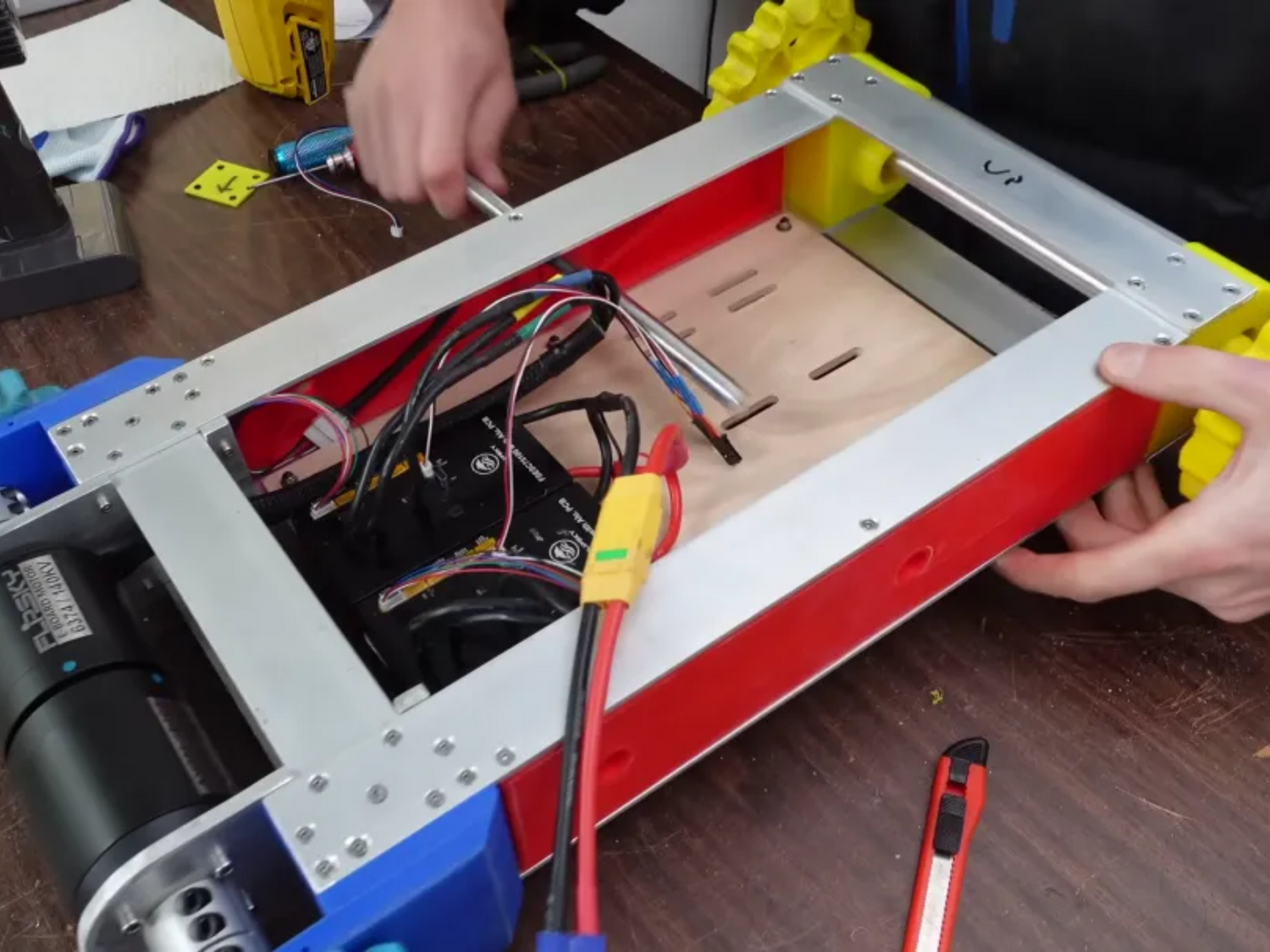

Daniel abandonou completamente o sistema tradicional de engrenagens e optou por motores elétricos de skate altamente personalizados. Com a ajuda da impressão 3D, a Guider 3 Ultra produziu rapidamente a maioria das peças estruturais necessárias, incluindo:

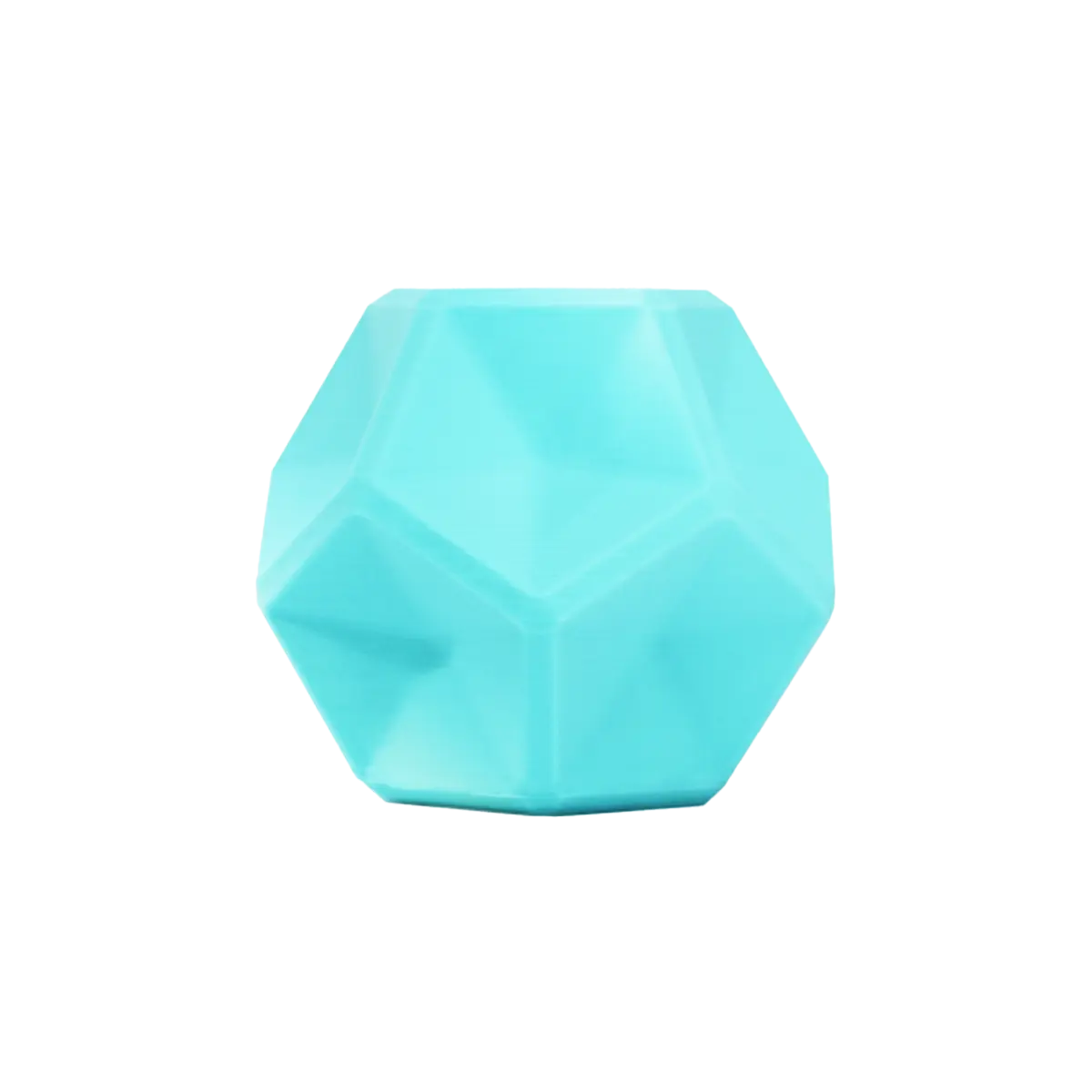

(Capa protetora do motor)

(Capa protetora do motor)

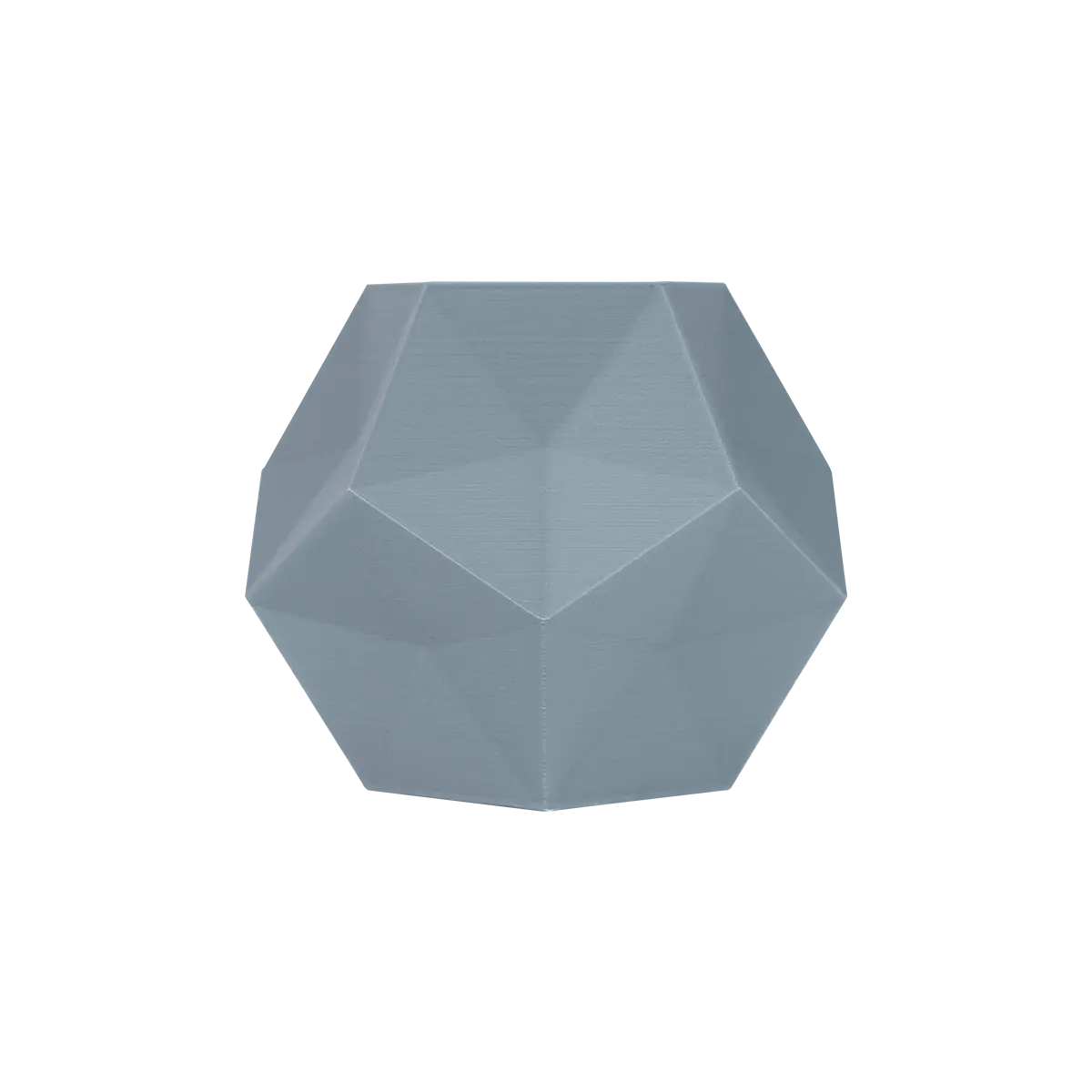

(Casca lateral da carroçaria)

(Casca lateral da carroçaria)

Estas peças, com furos, superfícies curvas e engrenagens, tinham de ser impressas com extrema precisão para garantir o encaixe perfeito entre os componentes – como o eixo e o suporte do motor, rodas e eixos rolantes, ou parafusos e furos – garantindo estabilidade e coordenação geral. A Guider 3 Ultra foi escolhida por Daniel como dispositivo de impressão para todas as peças, marcando a sua primeira experiência com uma impressora 3D. Com uma estrutura Core XY, oferece uma precisão e estabilidade de impressão melhoradas a altas velocidades, garantindo peças impressas em 3D de alta qualidade. Além disso, a sua plataforma flexível em chapa de aço facilita a remoção dos modelos acabados, poupando tempo e esforço.

Aplicação prática: sem pós-processamento, montagem direta

(Diagrama do Processo de Montagem)

Durante todo o processo de montagem, as peças impressas com a Guider 3 Ultra necessitaram de pouco ou nenhum pós-processamento e ficaram prontas para montagem imediatamente. A propulsão do moto de neve é feita por dois motores circulares, que necessitam de proteção. Do ponto de vista mecânico, o design de Daniel incorporava revestimentos curvos que suportavam forças de impacto mais elevadas, o que representava um grande desafio para a impressora 3D. Graças ao desempenho de impressão estável da Guider 3 Ultra, cada camada foi alinhada com precisão, garantindo uma colagem precisa entre elas. Isto não só garantiu a resistência das peças ao impacto, como também o acabamento suave e refinado das superfícies curvas.

Correndo pela neve

Após uma impressão e montagem precisas, o snowmobile apresentou um desempenho excecional durante os testes em condições reais. Todas as peças impressas em 3D do Guider 3 Ultra encaixaram perfeitamente, permitindo que o moto de neve deslizasse suavemente sem problemas, demonstrando uma excelente estabilidade e um elevado desempenho.

(Correr pela neve)

(Correr pela neve)

Conclusão: Uma nova era de fabrico personalizado

O Guider 3 Ultra foi a ferramenta-chave para o sucesso de Daniel na construção do moto de neve R/C mais rápido do mundo e destaca o imenso potencial da tecnologia de impressão 3D em termos de fabrico personalizado, produção rápida e redução de custos. Esta colaboração confirmou ainda mais a nossa crença de que a impressão 3D pode abrir possibilidades ilimitadas para todos os tipos de projetos personalizados.

Contacto com Flashforge

Tem uma história incrível sobre impressão 3D para partilhar? Adoraríamos ouvi-la e partilhar as nossas experiências! Não hesite em contactar-nos pelo e-mail mkt2@flashforge.com.