rctestflight, a popular tech YouTuber with 600K global followers, is passionate about mechanical modifications. His creative projects have been greatly enhanced by the Flashforge Guider 3 Ultra 3D Printer. Recently, he used this 3D printer to modify a Dyson vacuum fan, turning it into a small R/C plane with powerful thrust. As of now, the video on his YouTube channel has garnered 1.32 million views and 27,000 likes. This project highlights the Guider 3 Ultra's impressive capabilities in flexible manufacturing and rapid prototyping, with printed components meeting the mechanical, aesthetic, and assembly precision requirements for small R/C planes.

High-Quality, Fast Printing

Dyson's fan has a strong vortex suction, and rctestflight designed a custom shell to convert the fan’s suction into thrust. After measurements, he designed the shell, ensuring the air intake and exhaust ports aligned with airflow trajectories to maximize the fan's power conversion.

Initially, he tried printing the fan casing using resin-based technology to achieve a smooth surface. However, due to issues with light intensity control and scattered light, the print resulted in unwanted overhangs and small internal air bubbles, even after several attempts. Finally, rctestflight switched to the Flashforge Guider 3 Ultra, which printed the casing successfully on the first attempt. He was impressed by the printer's high success rate and stable performance.

In the post-processing phase, only a small amount of paint was applied to the internal surface, achieving the required smoothness. This improvement allowed for better airflow circulation inside the casing, ensuring the Dyson fan produced optimal wind power. The Guider 3 Ultra offers a printing precision of ±0.15mm, ensuring that the components fit perfectly, easily assembling into a functioning "wind thrust engine." After testing, the fan generated up to 260g of thrust.

Practical Application: Wing Production and Flight Testing

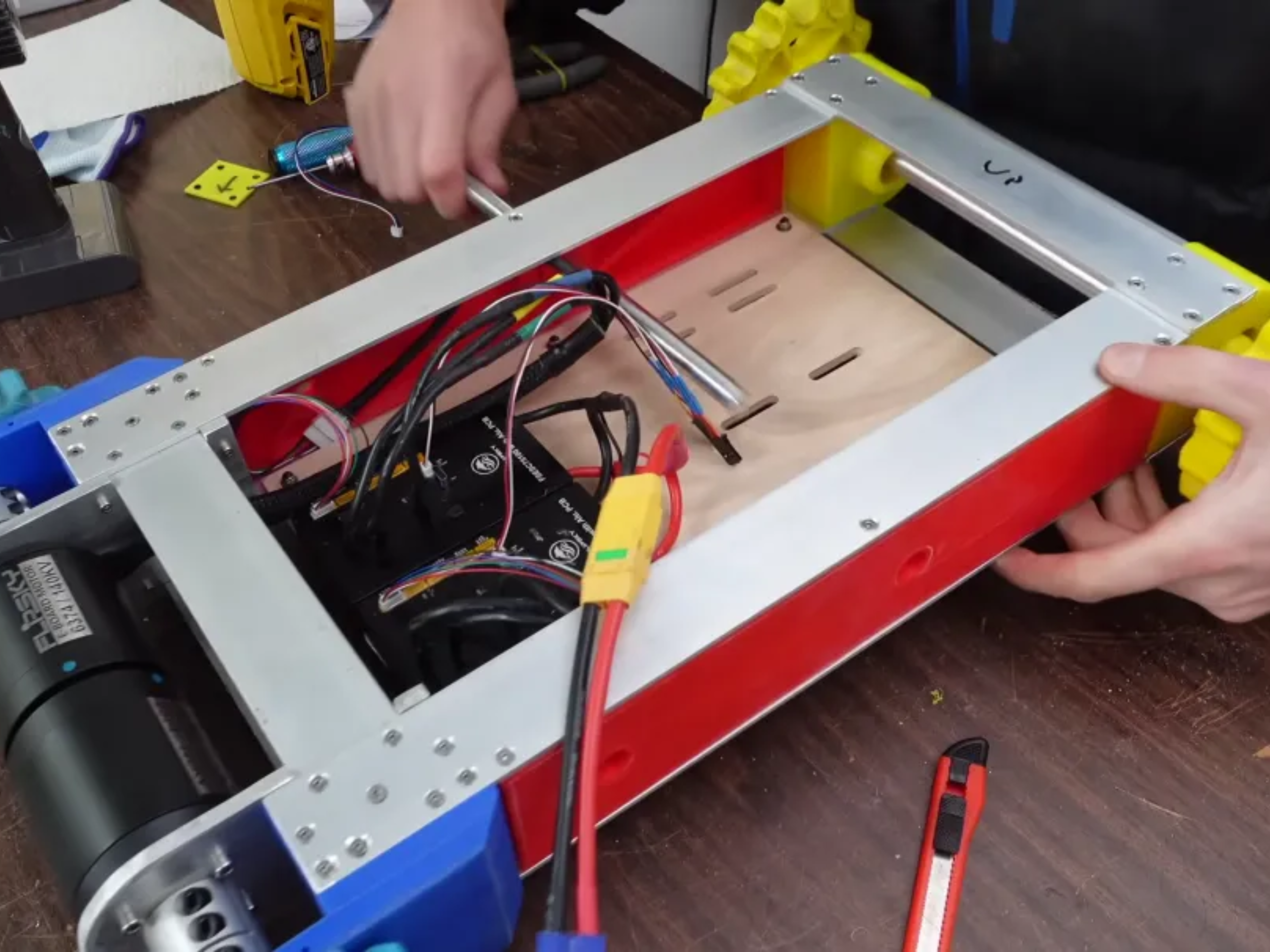

Next, rctestflight used lightweight materials and carbon fiber rods to create the plane's fuselage, wings, and tail, assembling them with two modified Dyson fans. The fans were installed on either wing, and by adjusting the fan power, the plane's direction could be controlled. The end result was a Dyson-inspired wireless R/C plane.

Large Build Volume

Additionally, the Guider 3 Ultra boasts a 330x330x600mm large build area, with a 600mm vertical Z-axis that’s perfect for printing various parts of medium and small-sized R/C planes. It even allowed for the printing of the small wings in one piece, saving time and eliminating the need for segmentation. The printer’s hotend temperature can reach 350°C, enabling high-quality prints with carbon fiber composites. The resulting parts are both lightweight and strong, making them ideal for R/C plane applications.

Conclusion: Unlock Your Creativity and Build Your R/C Plane

This project perfectly demonstrates the vast potential of the Flashforge Guider 3 Ultra 3D printer in personalized manufacturing. Whether for R/C plane modifications or other creative projects, the Guider 3 Ultra is the ideal tool for turning ideas into reality and boosting production efficiency. If you're ready to bring your creative projects to life, the Guider 3 Ultra is your indispensable partner.

Click the link below to learn more about the Guider 3 Ultra and start your creative journey today!