Looking for Help?

Find answers to your questions

-

Adventurer 5M Series

- FAQ for Adventurer 5M Pro

- FAQ for Adventurer 5M

- Unboxing Your Adventurer 5M Pro

- Adventurer 5M Series Firmware Update Log

- Firmware Upgrade

- Troubleshooting: Network-related Issues

- Troubleshooting: Equipment Error Messages

- AD5M Series Troubleshooting: Equipment Hardware Issues

- AD5M Series Troubleshooting: Print Quality Problems

- Troubleshooting: Equipment Usage Issues

- Basic Setup

- Accessories List

- Unboxing Your Adventurer 5M

- Introduction to Adventurer 5M Series

- FAQ for Guider 3 Ultra

- Perform a firmware update on Guider 3 Ultra

- Firmware release note

- Troubleshooting for Guider 3 Ultra

- Basic setup

- Accessories list

- Unboxing your Guider 3 Ultra

- Introduction to Guider 3 Ultra

- AD5X Firmware Upgrade

- Print Without IFS

- Print via Orca-Flashforge

- Print Models from a USB Flash Drive on AD5X

- Print Built-in Models on AD5X

- Change Filament on AD5X

- Loading Filament

- AD5X Printing on the Build Plate

- AD5X Preparation before Printing

- Refill Printing

- Automatic filament loading

- Multi-Color Printing

- Connecting IFS to AD5X

- AD5X Basic Setup

- Accessories List for AD5X

- Quick-start Guide for Your AD5X

- Unboxing Your AD5X

- Introduction to AD5X

- Print Built-in Models on Adventurer 5M Series

- Preparation before Printing

- Printing on the Build Plate

- Creative Designs from our Users

- Test print models for HS PLA (print with ad5m series)

- From 0 to 250: The Rise of a 3D Print Farm

- How to Series Video on Youtube

- AD5M Series Slicing Profile

- Maker Series Video on Youtube

- Page Contents

- Printer Mod and DIY

Troubleshooting: Equipment Usage Issues

Table of Contents

1. Filament Guide Tube Clogged.

Issue: During filament change, the filament cannot pass through the filament guide tube.

Cause 1: Uneven (inclined) surface of the filament end, making it get stuck at the filament detection position

Solution: Rotate the filament or trim the filament end, and then re-feed the filament.

Cause 2: Filament breaks off in the filament guide tube.

Solution: Remove the broken filament remained in the filament guide tube.

2. Filament Extrusion Issue.

Issue: 1. Under-extrusion; 2. No filament extrusion.

Cause:

1. Filament tangles;

2. Mismatched parameter settings;

3. Nozzle clogged;

4. Extruder clogged

Solution:

Step 1: Check if filament is tangled on the spool.

Step 2: Ensure the setting temperature of the nozzle matches the setting temperature of the current filament, and then perform filament loading. If no extrusion, remove the filament guide tube on the top of the extruder, hold the filament by hand, and push it downward to clear the blockage.

Step 3: If the above steps don't work, use the provided unclogging pin tool to clear the nozzle.

Step 4: If the above steps don't work, replace the nozzle.

Step 5: If the above steps still don't solve the problem, check for extruder blockage.

3. No Extrusion on the First Yayer.

Cause: Distance too close.

Solution: Re-level.

4. Model Not Sticking to the Build Plate.

Cause:

1. Build plate damaged or severe wear, resulting in an uneven surface;

2. Oil stains on the build plate;

3. Improper distance after leveling;

4. Incorrect parameter settings

Solution:

Solution 1:

Step 1: Clean the build plate surface by removing the oil stains and filament residues.

Step 2: Clean the nozzle by removing the residues.

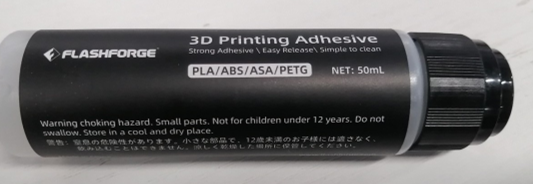

Step 3: Apply a thin layer of glue evenly across the entire build surface; The glue is provided with the machine, as shown below.

Step 4: Re-level and perform a test print. If the issue persists, please proceed to Solution 2.

Solution 2

Step 1: Update the firmware, enable leveling before printing, and conduct a test print.

Step 2: If Step 1 doesn't work, slightly increase the bed temperature by 5-10℃ based on the corresponding filament. For example, for PLA filament, set the bed temperature to 55-60℃; for ABS filament, set the bed temperature to 110℃.

Step 3: If the above steps don't work, manually raise the bed by 0.05-0.1mm during the first layer printing to reduce the distance between the nozzle and bed, thus improving adhesion.

Step 4: If the above steps still don't solve the problem, please copy logs to a USB flash drive and contact customer support.

5. Nozzle Scraping Against the Built Plate.

Issues: After automatic leveling, the extruder is too close to the bed when printing the first layer, causing the nozzle to scrape against the build plate.

Cause: Filament residues at the nozzle tip or uncleared print bed.

Solution:

Step 1: Clean the nozzle and bed by removing the residues.

Step 2: Restart the printer and perform automatic leveling again.

Step 3: If the above steps don't work, consider checking for firmware updates. Upgrade the firmware if a new version is available and retry.

Step 4: If the above steps still don't solve the problem, please copy logs to a USB flash drive and contact customer support.

6. No Filament Extruded During Filament Loading.

Issue: During filament loading, there is no filament extrusion or filament cannot be fed downward.

Cause: 1. Improper extruder installation; 2. Mismatched parameter settings; 3. Nozzle clogged; 4. Extruder clogged.

Solution:

Step 2: Ensure the setting temperature of the nozzle matches the setting temperature of the current filament, and then perform filament loading. If no extrusion, remove the filament guide tube on the top of the extruder, hold the filament by hand, and push it downward to clear the blockage.

Step 3: If the above steps don't work, use the provided unclogging pin tool to clear the nozzle.

Step 4: If the above steps don't work, replace the nozzle.

Step 5: If the above steps still don't solve the problem, check for extruder blockage.

7. Extruder Clogged.

Issue: 1. No filament extrusion during printing;2. No filament extrusion during filament change (a creaking sound is produced when manually loading filament).

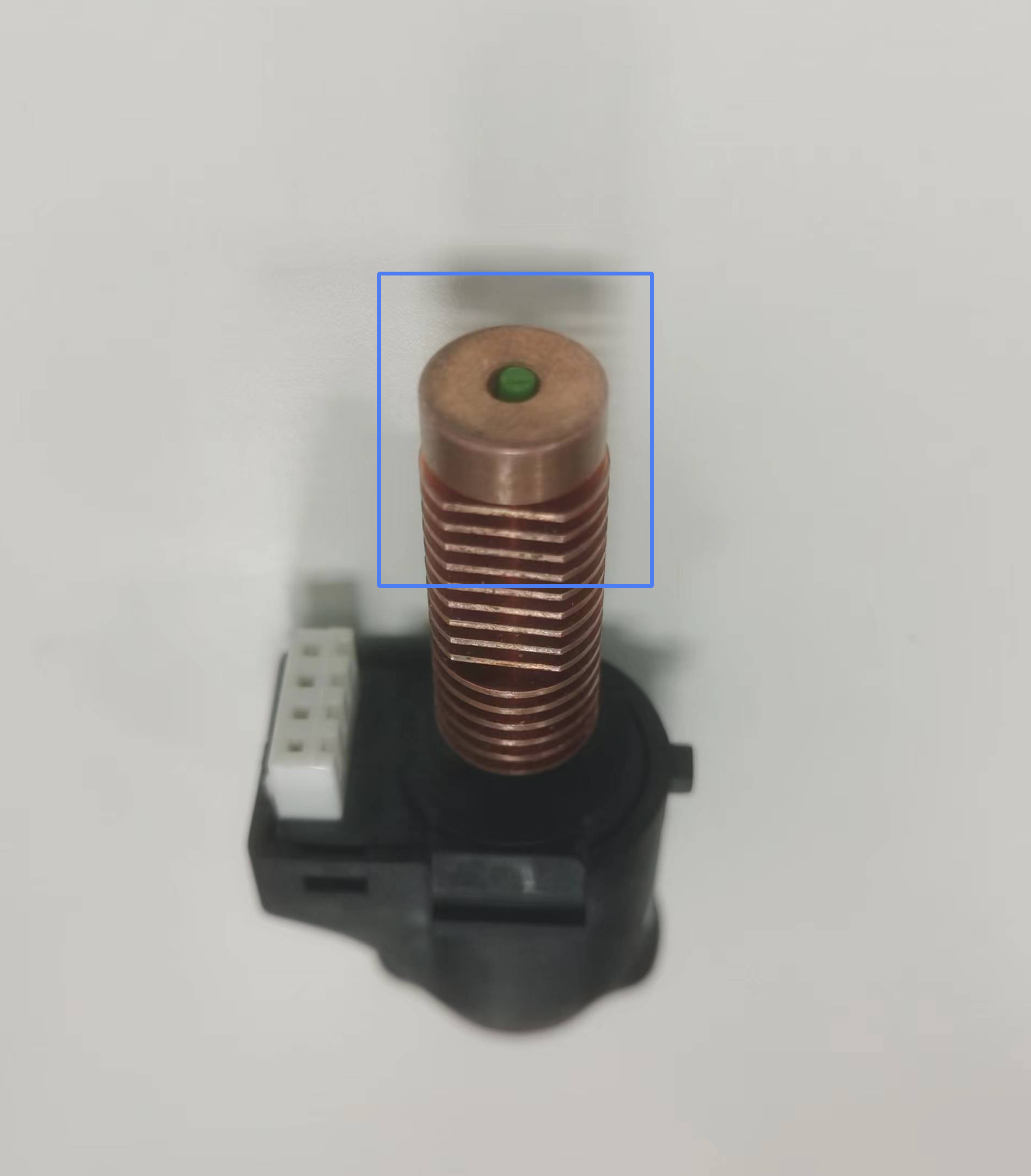

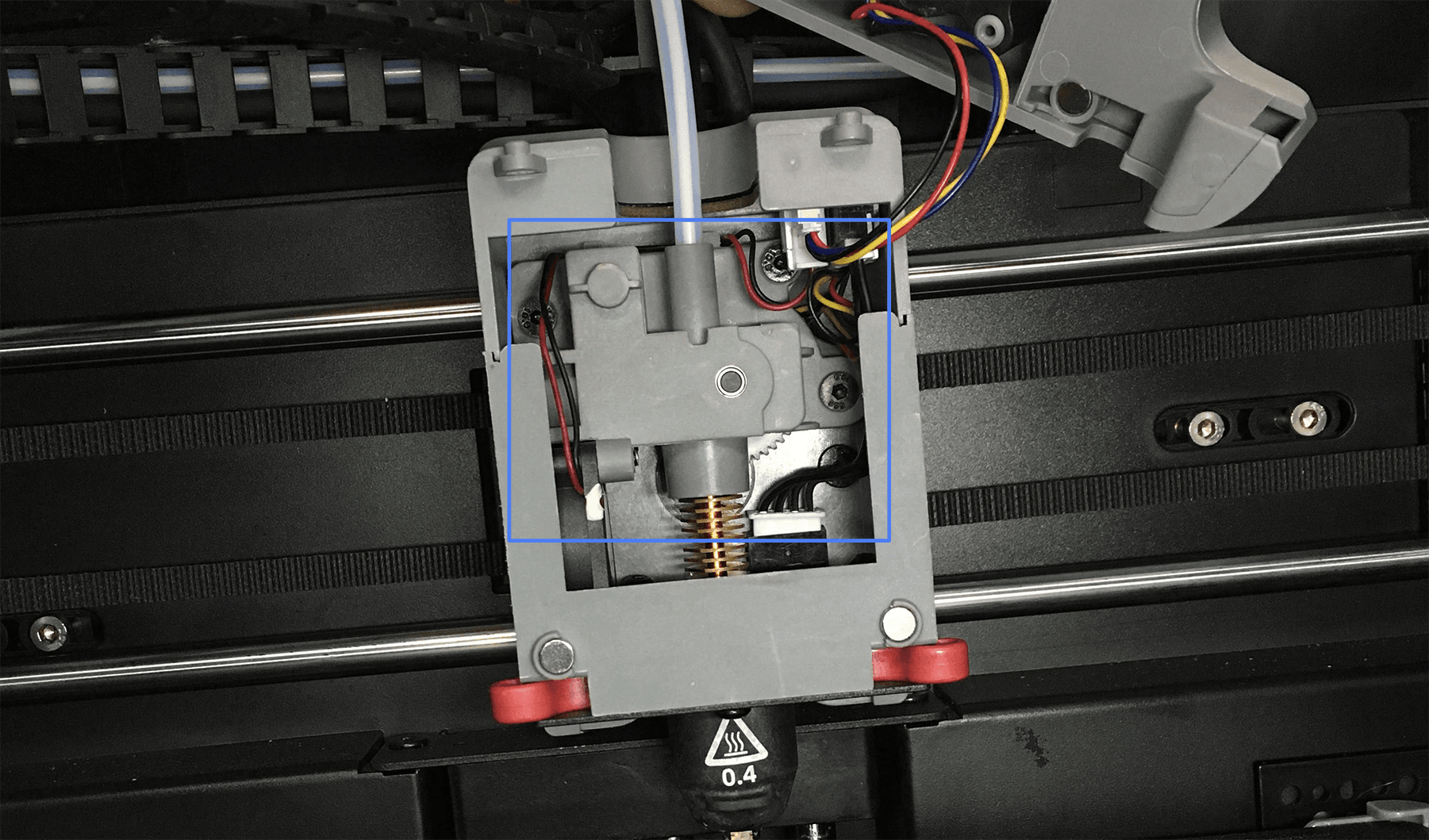

Cause: Extruder got clogged or the filament feeding gear of the extruder was slipping. Below is the position of the extruder.

Solution: Check for extruder blockage and clear the feeding gear of the extruder. For how to disassemble and fix the extruder, you can refer to this video on Youtube:

Updated on 31 Aug 2024

What are your Feelings?

Thanks for your feedback

Newsletter

Promotions, new products and sales. Directly to your inbox.

Free shipping

Available for shipping within the continental United States.

12-years Brand

Trusted by over 1 million users worldwide.

Secure payment

Pay securely with Credit Card, PayPal, Klarna, and Afterpay.

Points & Rewards

Just 100 points = 5% off on filaments and accessories.