As 3D printing applications diversify, generic PLA filaments no longer suffice for various practices. The need for high-performance filaments stems from the desire to address specific challenges and elevate the quality and functionality of printed objects. We need superior mechanical properties, enhanced thermal stability, resistance to harsh chemicals and many other functionalities beyond the capabilities of generic filaments. High-performance filaments, encompassing materials like ABS-ESD, PETG, ASA, Nylon, and more, have emerged to meet these exacting requirements.

1. The need for high-performance filament

While high-performance filaments acquire superior properties and functionalities, there are, at the same time, some challenges for better 3D printing techniques to match more demanding manufacturing requirements such as temperature control, higher durability of printer components and so on.

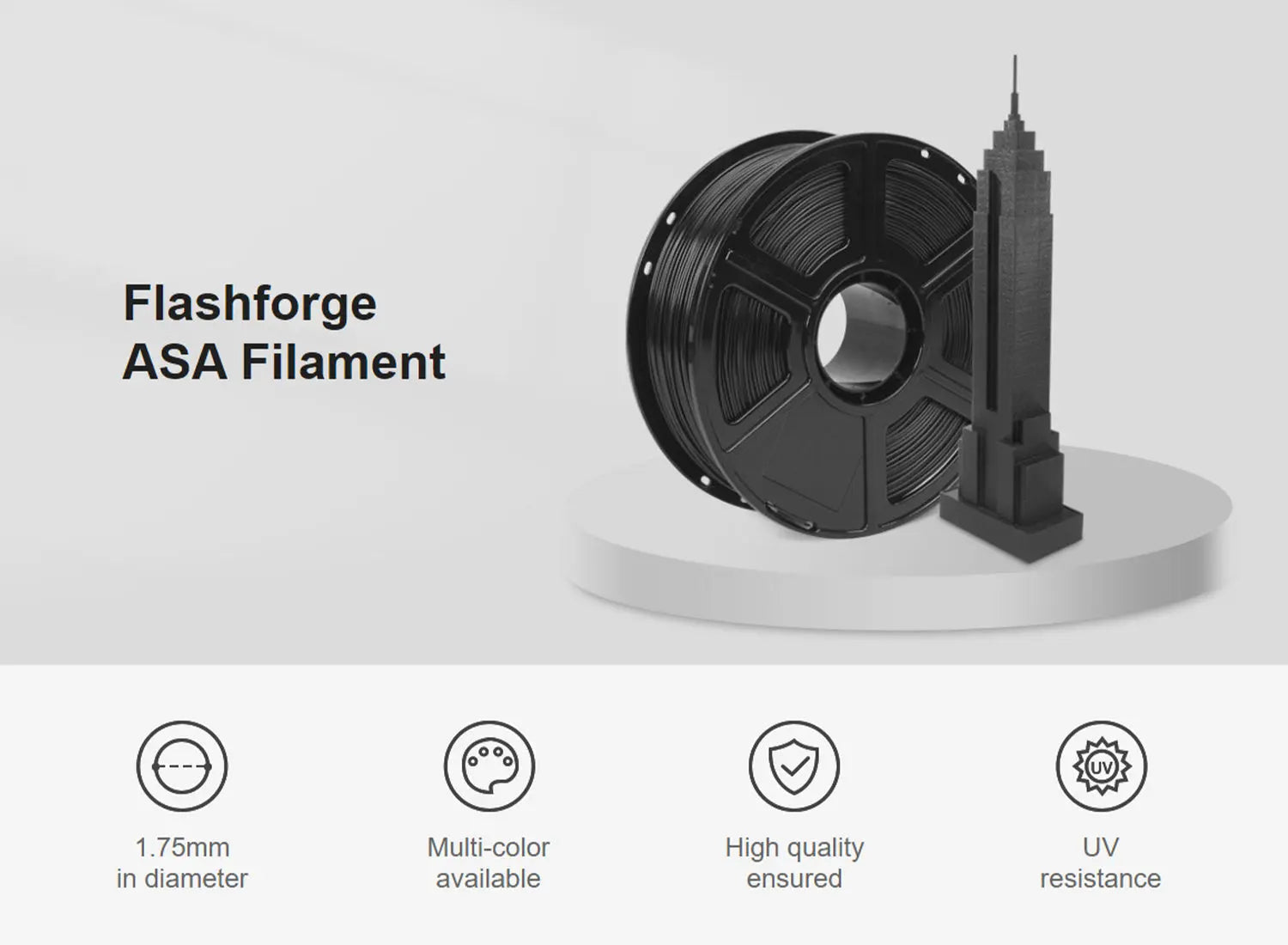

The inclusion of features like a fully enclosed printer and a hardened nozzle in the Flashforge Adventurer 5M Pro has significantly enhanced support for a broader range of high-performance filaments, elevating the capabilities of 3D printing applications to new heights. Flashforge's latest ASA (Acrylonitrile Styrene Acrylate) filament inherits the outstanding characteristics of ASA material, showcasing heat resistance, corrosion resistance, shape stability, fracture resistance, resistance to dirt, and UV resistance. Parts printed with ASA filaments can retain vivid colours and optimal performance over an extended duration, particularly when utilized in outdoor scenarios.

2. Flashforge ASA filament

In order to ensure that the filament possesses the outstanding characteristics of ASA material while also overcoming the challenges and downsides of the ASA material during the 3D printing process, Flashforge has incorporated meticulous considerations into ASA filaments.

Through the adjustment of the proportions of the three materials in ASA materials, Flashforge has heightened the release rate of thermal stress during the 3D printing process, addressing concerns related to cracking and deformation during model cooling. Additionally, the integration of lubricants in the filament enhances the melt flowability of the consumables, boosting extrusion efficiency when utilizing ASA filaments with 3D printers. This enables the printer to handle printing tasks at an accelerated speed. These technological advancements aim to overcome challenges associated with high-performance filaments and 3D printing, positioning Flashforge ASA filaments as a high-quality and beginner-friendly choice.

The chart below provides a comparison of technical parameters between ASA and PLA. The variation in tensile strength and flexural strength highlights that, in contrast to PLA, which is rigid but somewhat brittle, ASA stands out as a high-performance filament with notable impact resistance. ASA demonstrates the capability to withstand moderate mechanical stresses and impacts.

Besides, ASA is also known for its excellent weather resistance and UV stability, making it an ideal selection for applications and products exposed to harsh environmental conditions. This superiority over PLA filaments promotes an increased usage in outdoor applications, as prolonged exposure to sunlight and varying weather conditions is no longer a limiting factor.

3. Filaments comparison: ASA VS ABS

So, what are the common characteristics of ABS and ASA, and does ASA offer more than ABS? Below are some basic ideas for how the two filaments are similar to and different from each other:

The similarities:

Both ASA and ABS are thermoplastics composed of a combination of acrylonitrile, styrene, and acrylate. Both can be printed with FDM printers.

The material properties of ASA are similar to ABS, exhibiting excellent toughness, impact resistance and durability. The parts built with ASA can withstand impacts and stress and work well in harsh situations where other filaments like PLA are prone to breakage and material failure, such as yielding and buckling.

The bonuses for ASA over ABS:

ASA has superior resistance to ultraviolet light (UV), whereas ABS does not. This makes ASA a preferred choice for long-term outdoor applications where exposure to sunlight is a concern.

Besides, ASA exhibits excellent temperature and chemical resistance, making it suitable for outdoor applications exposed to higher temperatures and corrosion.

With these being discussed, ASA is often considered an upgraded version of ABS, offering better UV stability and temperature resistance.

4. Requirements and tips

The printing requirements for Flashforge ASA filament are also close to those of ABS. Below is a brief checklist of recommended parameters for printing with Flashforge ASA filament, and the settings for ABS and PLA filaments for supplemental reference.

It’s important to note that the ASA filament is highly recommended to be printed by printers with enclosed design and internal filtering functionality. The reasons are multidimensional, and we put several common explanations below:

- The materials, such as ABS and ASA, are prone to producing harmful gases and unpleasant smells during printing.

- Based on the material properties of ASA filaments, the printing process needs a higher nozzle and plate temperature compared to generic filaments, and part tends to warp during printing, especially if there exist sudden temperature changes. Enclosed design provides a better chamber temperature control that reduces warping and improve layer adhesion.

- The enclosed design provides a protection from external factors during printing such as moisture, dusts, and other impurities. This bonus combined with temperature control, enhance better overall print quality.

Note that the cooling fan should be set to low. The reason for this is straightforward. On one hand, turning on the fan is that it will prevent the overheating issues from affecting the print quality, on the other hand keeping the fan running slow prevents the temperature from dropping too much and warping will be more likely to appear. One should also slow the print speed down for ASA as this can help to minimize vibration, ensure consistent extrusion, and improve printing quality.

Without the proper printing environment, the ASA prints with too much residual stress and this causes the parts to warp or crack, compromising the mechanical strength of the part. These requirements bring up the necessity for an enclosed printer, facilitating more versatile printing tasks and unrestricted creativity.

5. What you can do with this filament

With the mechanical properties, structural performance and durability, the ASA filament is ideal for applications such as exterior signage, handles, automotive parts, garden tools and accessories, outdoor devices, 3D printer customization, and you name more usages.

We've also created several prints for daily usage as a quick and intuitive glimpse, showcasing the potential application of Flashforge ASA filament.

Example1. AD5M Filament Holder (Designed by LXD )

Example2. Alternative Handle (Designed by Flashforge)

Example3. Desktop Organizer (Designed by Flashforge)