Looking for Help?

Find answers to your questions

Introduction to Adventurer 5M Series

Table of Contents

This article provides a basic overview of the mechanical structure and electrical components of the Adventurer 5M series for you to have a good grasp of the Adventurer 5M series.

Working Principle of Adventurer 5M Series

The Adventurer 5M series prints 3D objects by melting filament, extruding it from the nozzle, and depositing them layer by layer.

For 3D printing, the most common type of model file is the STL format, which can be converted into a format recognized by 3D printers (e.g., GX/G/G-code) using slicing software (e.g., FlashPrint 5). These files contain instructions to precisely control where to move, how fast to move, what path to follow, and parameters like temperature and speed.

CoreXY Structure

The CoreXY mechanism employs two motors working in unison to control the movement in both the X- and Y-axes. Movement along the X-axis occurs when both motors rotate in the same direction. Movement along the Y-axis occurs when both motors rotate in opposite directions. This design ensures precise and stable movement and allows for rapid acceleration.

The CoreXY structure offers several advantages over traditional 3D printer structures:

1. less inertia. The motors in the CoreXY structure can move simultaneously, so it has much less inertia than other structures. This allows the extruder to be more stable when moving at high speeds, reducing vibration and wobble and improving print quality.

2.higher speed and accuracy. With two motors moving simultaneously, the CoreXY structure can realize higher printing speed. Moreover, by accurately controlling the movement of both motors, higher printing accuracy can be realized, and more detailed models can be printed.

3. Smaller space occupation.The cross-over arrangement of the drive belts in the CoreXY structure results in a more compact path of motion for the extruder. The CoreXY configuration requires less space than other configurations and saves printer bed space.

4.Better stability and reliability. The two drive belts in the Core-xy structure intersect with each other to form a bi-directional tension balance, which effectively eliminates errors caused by inconsistencies in the belt tightening and loosening. This design not only improves the stability of printing, but also extends the life of the printer.

For more information about the CoreXY motion system please visit this link

Z-axis

The Z-axis of the Adventurer 5M series is composed of three lead screws, which are connected to Z-axis stepper motors via belts.

The heated bed has a pressure sensor at its base, enabling automatic Z-axis height calibration and leveling for a flawless first layer.

Extruder

The extruder feeds the filament to the hot end where it is then melted and extruded. Then 3D objects are created by layer-by-layer deposition of filaments.

The nozzle clips secure the hot end, which can be quickly removed by pressing both clips at the same time.

The cooling fan cools the heat sink to prevent nozzle clogs.

Hot End

The hot end heats, melts, and extrudes the filament layer by layer.

Optional hot end are available in three sizes: 0.25mm, 0.6mm and 0.8mm(* 0.25mm and 0.4mm Nozzle are made of stainless steel; 0.6mm and 0.6mm Nozzle are high-strength steel).

Suggest:Print PLA,PETG with 0.4mm or 0.25mm nozzle;print TPU,PLA-CF and PETG-CF with 0.6mm or 0.8mm nozzle.

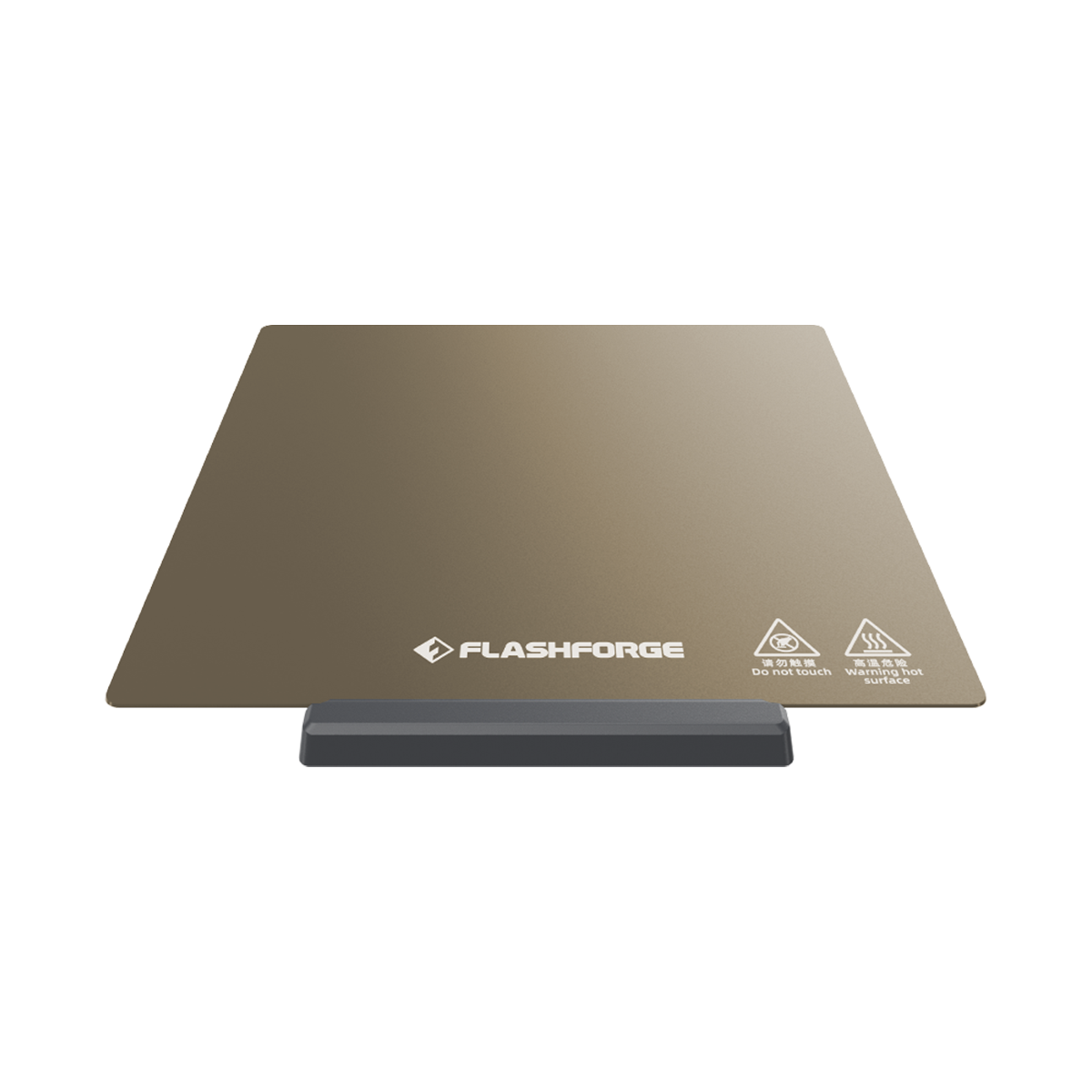

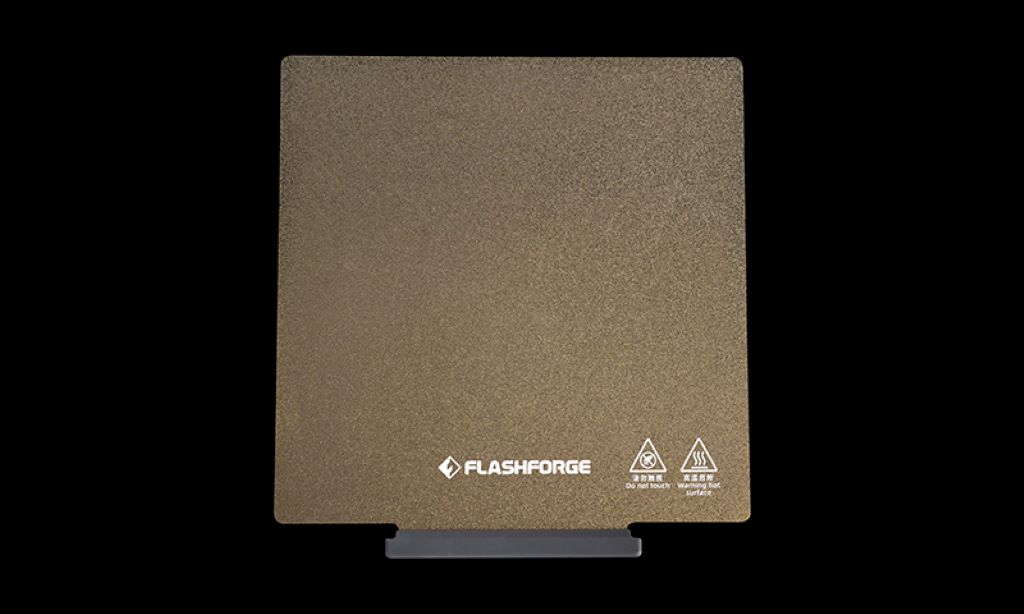

Heated Bed

The heated bed is a 3D printer bed that can heat up to various temperatures. Within a suitable range, the higher its temperature, the stronger the bed adhesion, reducing the risk of warping. The Adventurer 5M series's heated bed can heat up to 110°C.

Build Surface

The Adventurer 5M series is equipped with a flexible removable PEI steel sheet that can be used for printing filaments like PLA, PETG, and TPU etc.Refer to this link for instructions on how to use the PEI plate.

Cooling System

|

|

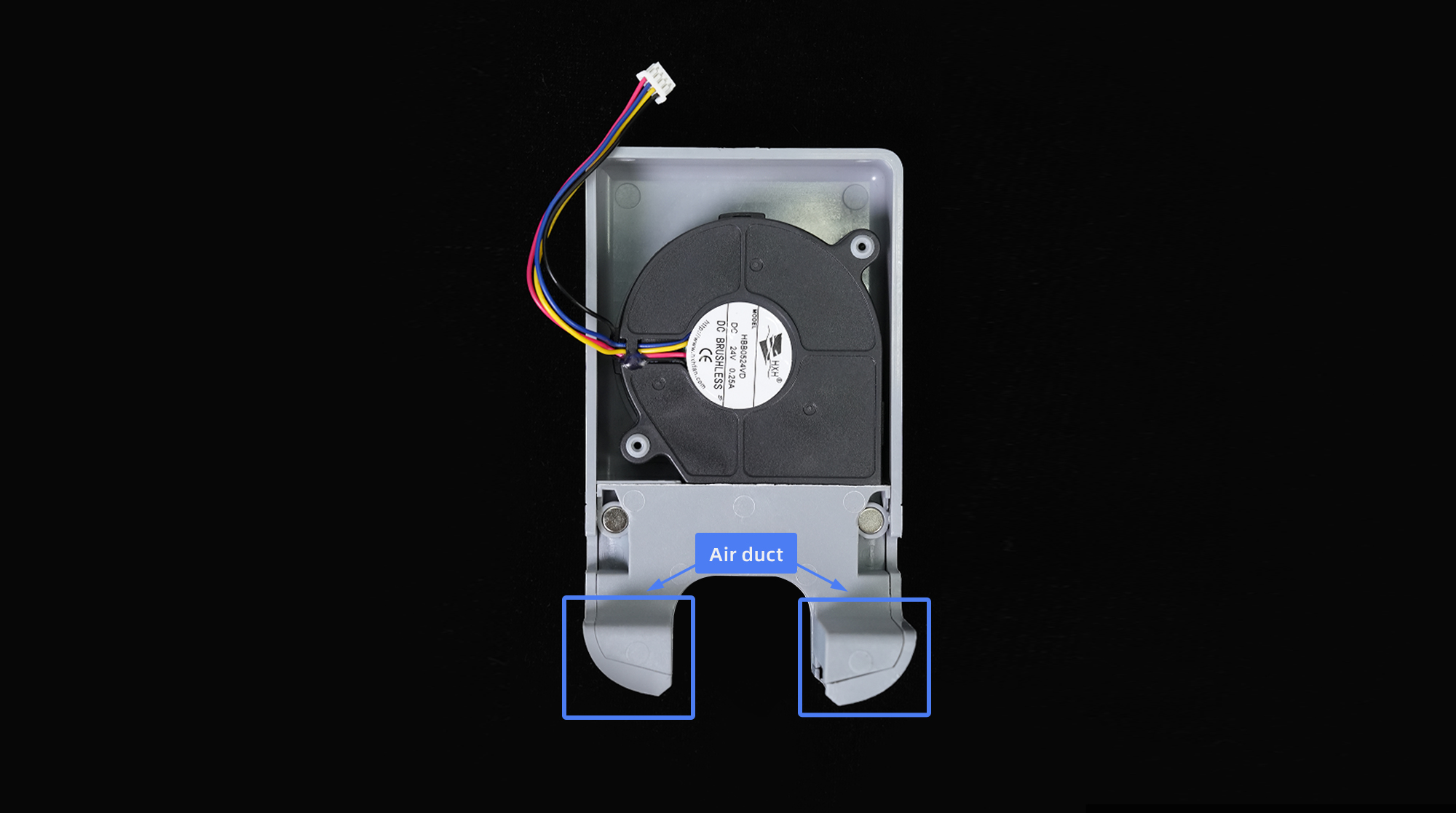

The Adventurer 5M series is equipped with a model cooling fan, and the air ducts at both sides ensure comprehensive model cooling during the printing process.

Adventurer 5M Pro is additionally equipped with an auxiliary cooling fan for more efficient and faster cooling of the chamber, improving the print quality.

Air Filtration System

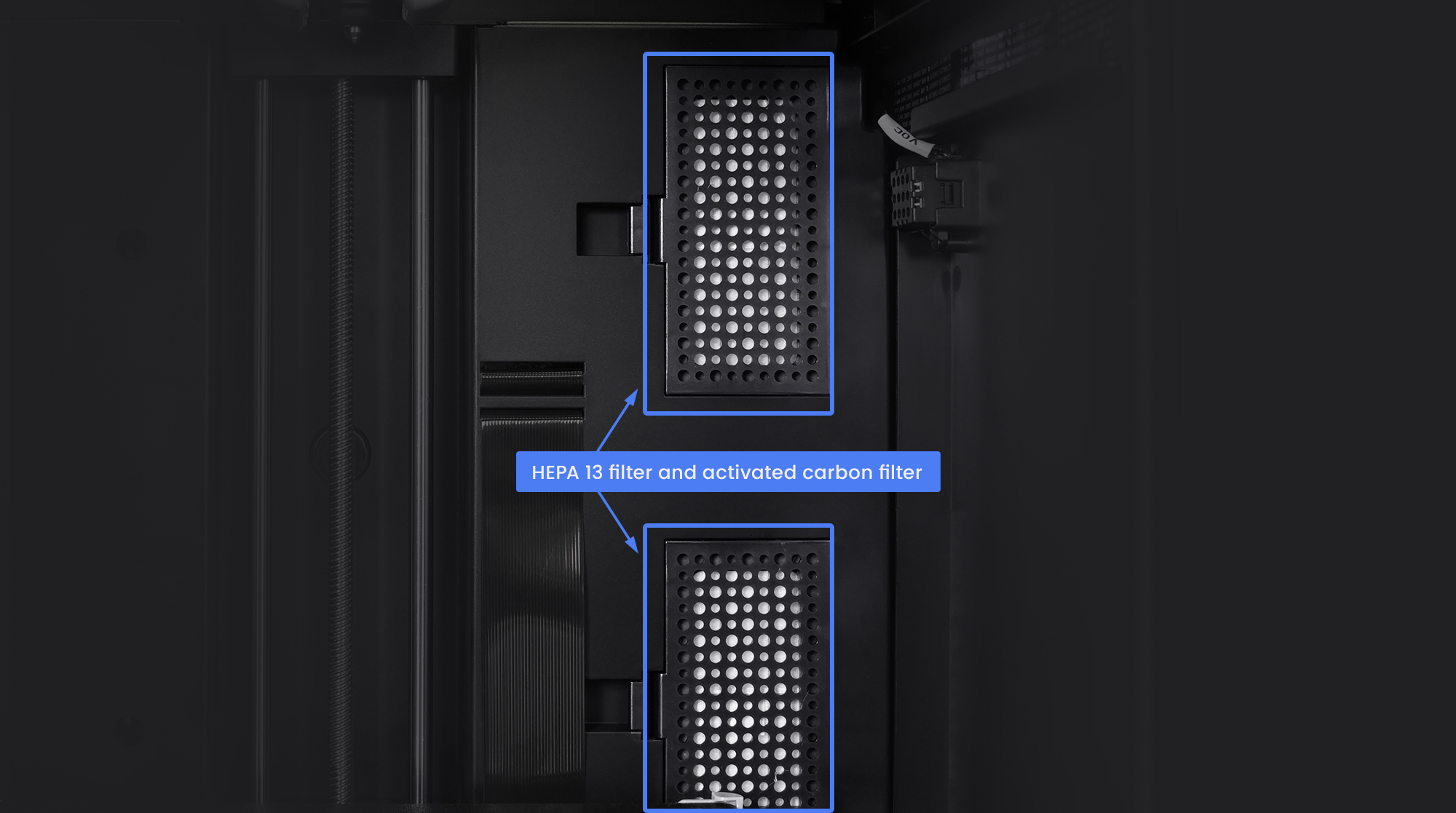

3D printers can release fine particles and volatile organic compounds (VOCs) during operation.

Adventurer 5M Pro possesses a dual filtration system of internal and external circulation. It also adopts a dual-layer filter system of HEPA and activated carbon, effectively blocking 99% of particles and VOCs, ensuring a safer working environment.

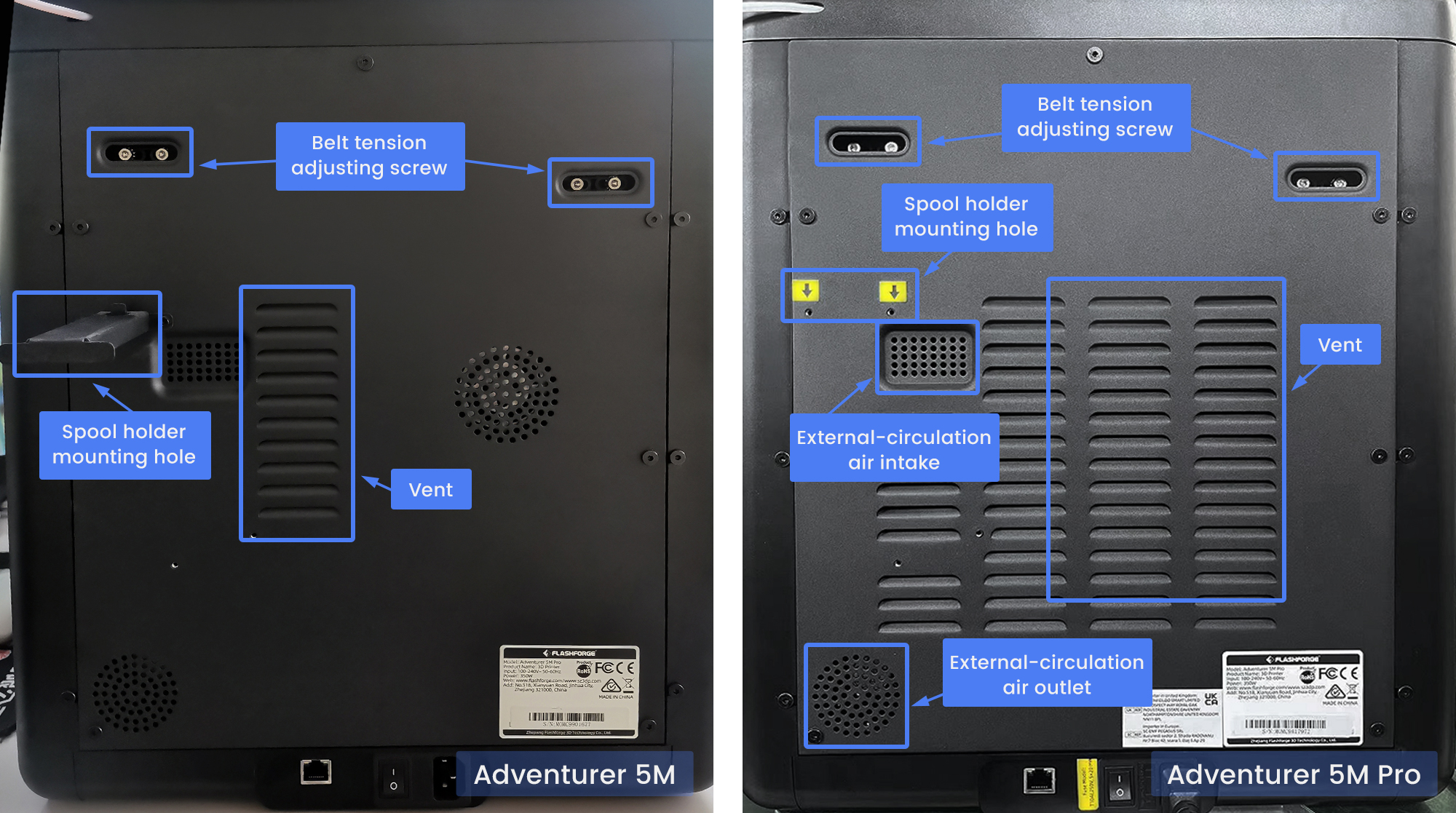

Printer Back

Belt tension adjusting screw for adjusting the belt tension to an appropriate level.

Spool holder mounting hole for installing a filament spool holder, offering convenient use.

Electrical Components

The Adventurer 5M series features various electrical components. Here are just some key ones.

Motherboard

The motherboard of the Adventurer 5M series uses a dual-core Cortex-A7 MCU, 8GB built-in storage, silent drivers, 5G & 2.4G Wi-Fi, and a TVOC sensor.

The CPU can enable functions like automatic shutdown upon print completion, pressure compensation, automatic leveling, and vibration compensation.

Pressure Sensor

The Adventurer 5M series uses a one-click full-auto leveling system, measuring the relative height between the nozzle and the platform through pressure sensing technology and performing automatic compensation. No need for leveling tools or manual Z-axis calibration, ensuring perfect first-layer quality.

Camera

Adventurer 5M Pro is equipped with a camera, allowing you to monitor the printing process via the slicing software or the Cloud. The printer automatically captures photos during printing and creates time-lapse videos. Upon print completion, you can view the photos and videos directly on the printer or export them.